Automated Biosensor Printer

Senior Design Capstone: Team Pressign Matters

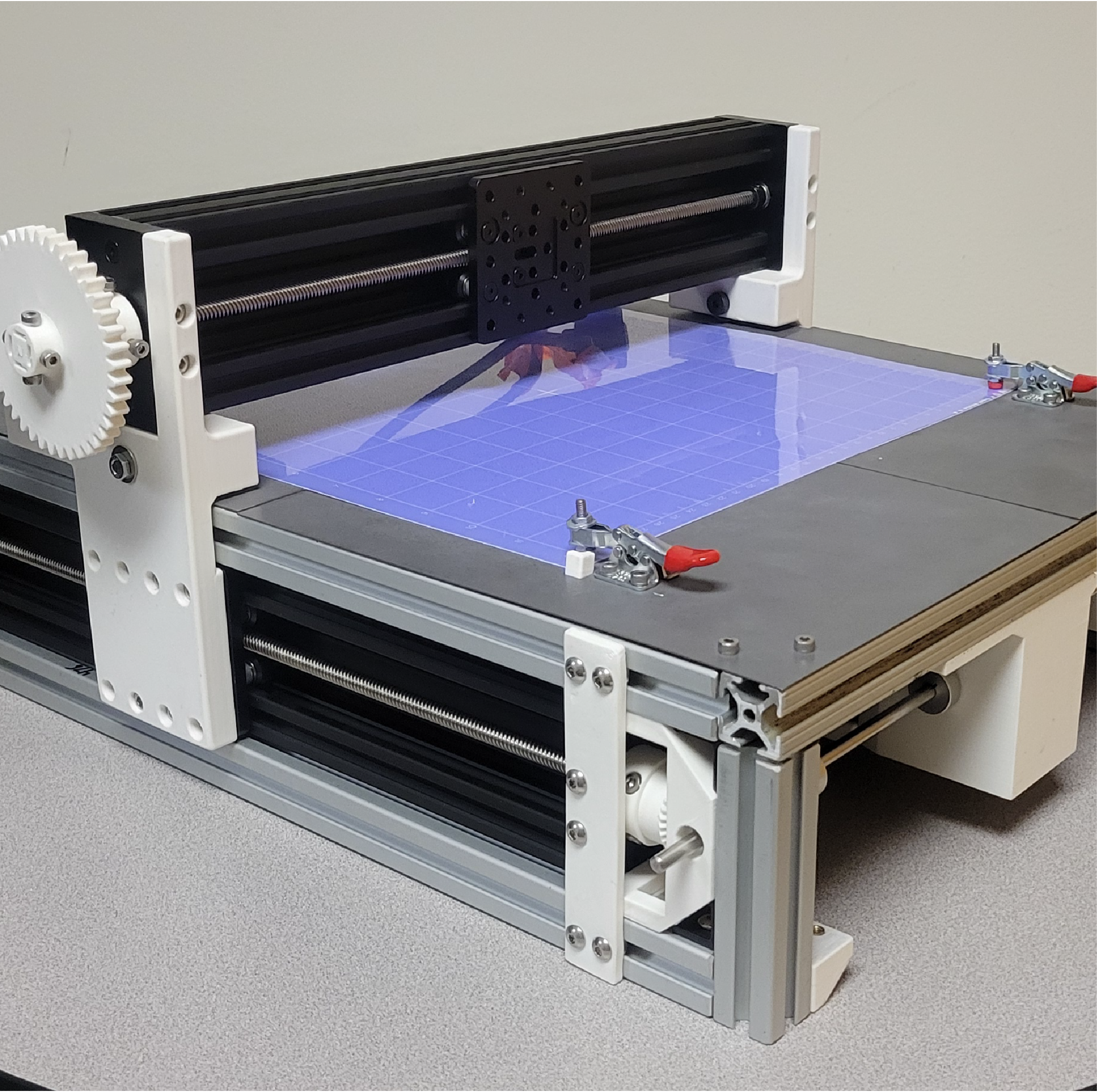

The Sempionatto Research Group develops wearable biosensors that collect and analyze sweat, blood, and other biofluids to monitor the wearer’s health. These wearable sensors must be flexible and thus are made by screen printing the electrode design with a conductive ink. Since existing screen-printing machines are bulky and expensive, the electrodes used in these sensors are often screen-printed by hand, which is time-consuming, inconsistent, and wastes a large amount of ink. The goal of this project is to build a desktop-sized printer that automates this process while minimizing wasted ink. The mid-year checkpoint that summarizes the work can be found at the bottom of the page.

Personal Contributions

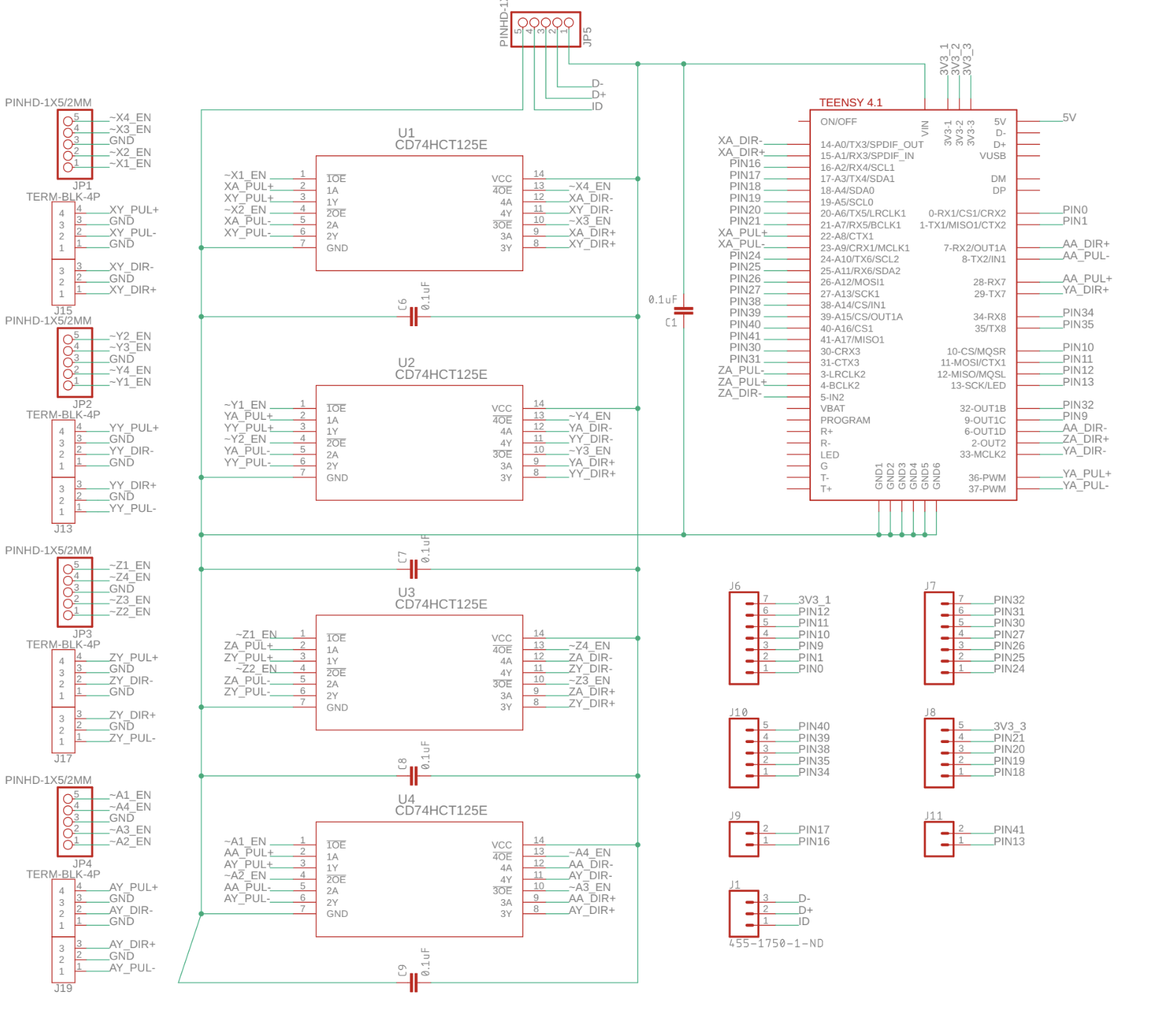

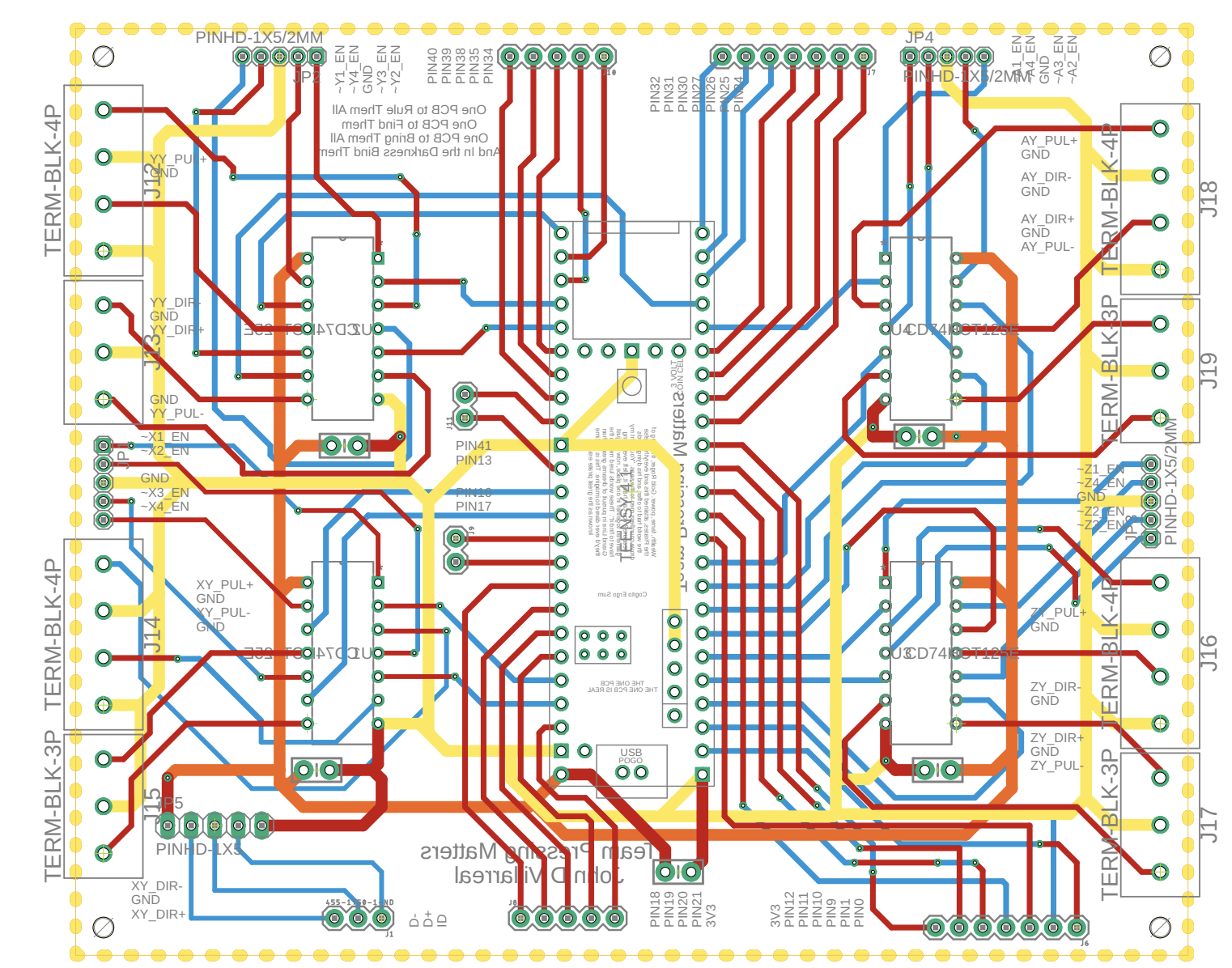

Printed Circuit Board

I independently designed and developed a printed circuit board (PCB) that utilizes various circuit components and devices to control the automated printer. The PCB is a 4-layer board that incorporates signal layers, a power plane, and a ground plane. The board incorporates a Teensy 4.1 Microcontroller, which is able to drive the motors on the printer and manage the user-interface. Additionally, the PCB contains various anti-electromagnetic interference (EMI) and noise protection features, such as bypass capacitors and a dedicated ground plane. Onboard Screw Terminals and Header Pins allow for the PCB to interface with external systems such as the motors and user-interface.

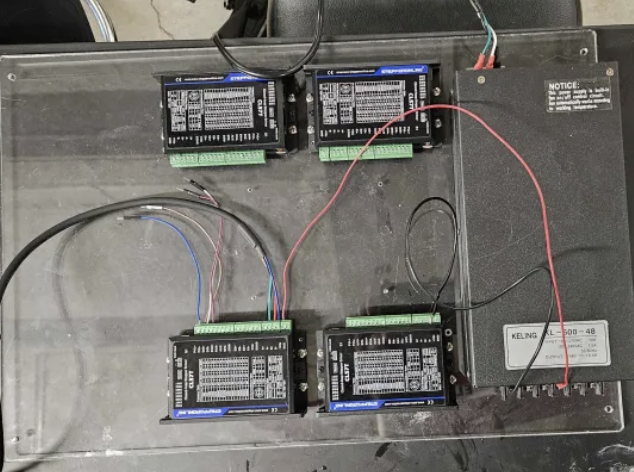

Electronics Undercarriage

I configured the layout of the Electronics Undercarriage, which is the plexiglass sheet used to house the motor drivers and power supply, to maximize usable space while still remaining under the allotted spatial design constraints. The configuration contains four motor drivers - used to control the motors based on microcontroller input - that I specifically selected for the motor driver’s high precision as well as for features such as opto-isolation and differential signaling.

Meet the Team!

This project is comprised of four team members: myself, Katie Noonan, Bradley Ramsey, and Hayden Webb (The latter 3 being Mechanical Engineering Majors). The team is broken up into two subsections - Electrical and Mechanical - of which serve to prioritize tasks based on individual specializations. As previously mentioned above in 'Personal Contributions', I created a custom PCB that utilizes and interfaces with commercially available products to control the Brushless DC Motors. The Mechanical Subteam, worked on the Computer-Aided-Design (CAD) Drawing of the Printer and assembled the printer using the CAD Design.

From Right to Left: Katie Noonan, John David Villarreal (self), Bradley Ramsey, and Hayden Webb